Boliden Odda: Building for the next 100 years

At the end of Sørfjorden, an arm of Hardangerfjorden a three-hour drive by car from Bergen in Norway, amid high mountains, waterfalls, and deep fjords, is a small industrial town named Odda. Here, the metals company Boliden is currently making a major investment to expand and upgrade its zinc smelter. The aim is to significantly improve productivity of the plant and further increase the output of zinc—mainly used to prevent rusting and prolong the lifetime of metals—while maintaining the smelter’s world leading environmental performance.

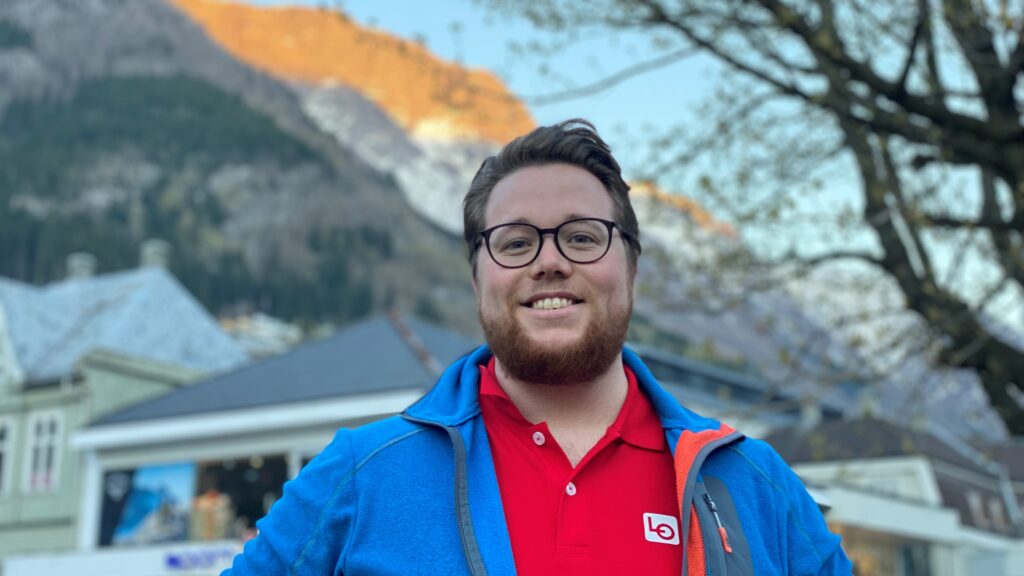

Arriving in Odda in early spring, the first person I see on the quiet streets of the town is a young man hanging up Labour Day posters on the small-town houses along the docks on the peninsula, or “odde” in Norwegian. He introduces himself as Tommy Tverdal, the main representative of the trade union Fagforbundet in the municipality of Ullensvang, and leader of the labour union LO in Indre Hardanger.

He seems pleased with the fact that the Swedish Boliden is now investing EUR 700 million to increase production capacity by 75% to 350,000 tonnes zinc. The expansion will create a need for around 3,000 new safety inductions for people coming to work at the plant during the project. The new Boliden Odda will give work for an additional 60 people on top of the 300 employees working here today.

“The large investment to expand Boliden Odda is creating new jobs and that will have major ripple effects on other companies and subcontractors in the region as well as other suppliers with a connection to Boliden,” says Tommy Tverdal.

“It is also positive for transport, schoolteachers and the health personnel at our local hospital—which we often need to fight to keep—and an important factor in creating local growth. Most people here appreciate the development, and I think it will make many proud to say that they are from Odda,” says Tommy, adding that “Boliden is an important part in that people from here can go with their chest and head held high.”

“The current shop stewards at Boliden Odda also sits on the group board of Boliden. In my experience they work well together, and we support what is happening. We want development in Odda.”

The Odda smelter

What attracted heavy industry to Odda and similar places in fjords and valleys in Norway around one hundred years ago was the availability of huge waterfalls that gave rise to the construction of hydropower plants with a massive local output of electricity. This is what made power-intensive industry possible in Norway and a reason why The Norwegian Zinc Company was established in Odda, surrounded by 1,500 metre high mountains, already in 1924.

Today, Boliden Odda has a yearly production capacity of 200,000 tonnes of cast zinc. Shipments are made weekly and 95% is exported to Europe, much goes to steel producers. As a biproduct, the smelter also produces sulfuric acid, which is shipped out less frequently. The raw material for the production is rocks with a 50% concentration of zinc, mostly from Boliden’s mines in Garpenberg in Sweden and Tara Mines in Ireland. That makes Odda one among the busiest harbours in Norway.

Concern for the environment is foremost at Boliden Odda. For example, the residues from the zinc production are safely deposited in 19 mountain caverns using unique sustainable technology to avoid polluting the fjord.

When Boliden announced the expansion on 21 July 2021, flags went up all around in Odda and in the municipality of Ullensvang. The expansion works started immediately after, and will see the building of a new roaster, sulfuric acid plant and cellhouse as well as the expansion and modernisation of the leaching and purification plants and foundry and quay infrastructure. Despite the substantial upgrade, the management of Boliden Odda confirms that production will run at full capacity until the expansion works are commissioned at the end of 2024, and that preparations are underway for marking the 100th anniversary and completion of the expansion project.

Arriving at Boliden Odda

The sun has been up a while above the mountains and is slowly warming the chilly spring air as I arrive at the entrance of Boliden Odda to meet with Helene Seim, General Manager, and Johan Abrahamsson, Project Manager. The security guard gives me a yellow helmet that will certainly single me out as a visitor to watch out for, as well as safety glasses, a neon-coloured jacket and safety shoes, and points me in the direction of the administration building.

On the work desk of Helene Seim, I recognise the Drive Award 2021 that she received on behalf of Boliden Odda last autumn. The glass sculpture is the green innovation award of Vestland County given in recognition of the management’s innovative ideas and potential to accelerate the green transition. Helene Seim points out that Boliden Odda is already one of the most climate efficient and productive zinc smelters globally.

“It is of course very nice to receive recognition for our work promoting the green transition, even if we are almost one hundred years old. Still, we are very modern and have long worked to reduce our environmental footprint while increasing efficiency. This large investment will further strengthen our efforts to retain Boliden Odda’s position thanks to the digitalisation, automation and new technology that will be introduced as part of the expansion,” says Helene Seim.

Boliden Odda is aiming for a 35% reduction of operating cost per tonne, due to economies of scale, automation, and digitalisation as well as a new hydro power agreement. Of the total EUR 700 million investment, the Nordic Investment Bank’s contribution is an eight-year loan of EUR 100 million.

“What I think is important, and which is why NIB is part of the financing, is that we need metals to make the green transition happen, and we have a very low CO2 footprint compared to other zinc producers, not to mention a sustainable way of disposing of our waste, which is quite unique,” says Helene.

Liisa Vuorinen, Senior Client Executive at NIB, says that the Bank has co-financed several of Boliden’s projects during a long business relationship.

“We are happy to also be part of this important project for Boliden Odda. We see the continued investments into the sustainability and productivity as the way to the future and are glad to be able to support Boliden on this journey,” says Liisa Vuorinen.

While writing this reportage, Lisa Vuorinen receives an email from Max Zetterström, Group Treasurer at Boliden, who writes: “Having worked with NIB over several years, we continue to appreciate the efficiency with which NIB takes on a large loan project, as is often the case with Boliden. We view an approved NIB loan as a stamp of quality for our projects and consider it an important contribution to ESG- and-climate supporting investments.”

The expansion

Back at the Odda smelter, Johan Abrahamsson tells me the project has started well despite the Covid-19 pandemic and war in Ukraine, but that they face some uncertainties in procuring the materials needed.

“We notice it is a different world out there, but so far the project has gone according to plan. Of the planned three million project work hours we have just passed 100,000 hours,” says Johan Abrahamsson.

He says around one thousand people will be working simultaneously on-site during the expansion project. To house all the workers, they will build a floating hotel in the docks with 600 beds, and a smaller barracks on land with 200 beds.

So how is zinc produced?

A tour of the plant provides a rudimentary understanding of the process and upgrade works in process. In short, they are setting a new standard for zinc smelting in terms of both sustainability performance and cost effectiveness. The longer explanation is a classic “don’t try this at home”.

The ships arriving at Odda offload concentrated rock masses containing 50% zinc as sulphide into a roaster. The furnace heats the mass to form zinc oxide and sulfuric dioxid. The hot zinc oxide continues for leaching in a purification plant where the zinc oxide is dissolved in the sulphuric acid to extract the zinc nucleus, copper and cadmium. Once the new purification plant is up and running, it will be able to purify additional metals such as lead, silver and gold, while reducing residues.

“As with everything else in life, there is significantly more lead than gold!” Johan Abrahamsson says, laughing.

Up next is the purification process in the cell house that liquidises the zinc. Some 80% of the electricity usage in the production process is spent here.

“You put metal plates into the zinc sulphate solution and, with the help of electricity, and the zinc attaches to the cathodes. What we get are a few millimetre thick three-square metre plates of zinc with a purity of 99.995%. We then lift the cathode and peel off the zinc, which then goes into the foundry where it is smelted and cast into blocks of different sizes,” Johan explains, adding “we also produce a range of products of different alloys, which can be copper, aluminium or nickel and which are custom-made for our customers.”

A significant part of the new equipment will come from Finnish Metso Outotec, another customer of NIB.

“No other smelter will be more productive than this one after the expansion,” says Johan.

“That is because we build to scale, exchanging small units for larger ones with a large portion of automation and digitalisation. That will allow us to increase production with 75% and employees with 20%, so it is a considerable increase in productivity.”

“We have a new licence to operate based on the increased output, which is tougher than what we have for our current capacity. That is part of the dynamic between the environmental authorities and the industry,” says Johan.

The next 100

Another important relationship is that between the smelter and the local community. Helene Seim was born in Odda and grew up there. Her father worked as an operator in the electrolysis hall. Back to Tommy Tverdal who talked earlier about the local ripple effects from the Boliden Odda expansion.

“Yes, this is extremely important also for Odda and the municipality. We are a keystone company, which is important for suppliers and for jobs here in Odda and Ullensvang. We work closely with the municipality and the companies here, so whether we hire an engineer or an economist we seek to be helpful in finding a job for those with a life partner. That is an important part of the collaboration we have here,” says Helene, adding “We are building for the next hundred years.”