Turning the page in steelmaking – A fossil-free future awaits in Luleå

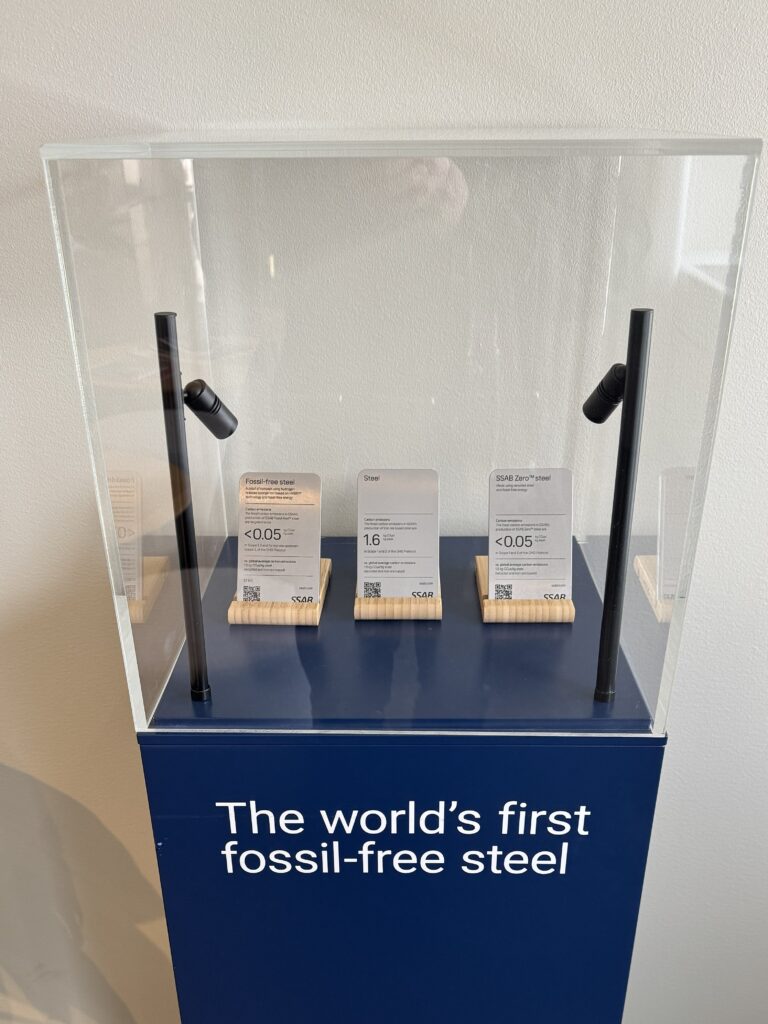

A fundamental transition in the steel industry is underway in Luleå, northern Sweden, as the construction of SSAB’s new fossil-free steel mill is proceeding at full speed.

The smokestacks of SSAB’s old mill loom over the construction site, reminding us of the soon-to-be past, as the old mill will gradually be shut down once the new one becomes operational. Electric arc furnaces are replacing the traditional blast furnace system, as the new mill is set to start production by the end of 2029.

“We’re leaving the coal-based economy behind, for a future, driven by fossil-free energy,” SSAB’s Chief Technology Officer Carl Orrling explains to me at the company’s Stockholm headquarters.

The old mill in Luleå was designed in the 1950s and 1960s, and SSAB knew it was necessary to modernise the manufacturing setup. The company’s Science Based Targets initiative (SBTi) goal is to achieve net-zero greenhouse gas emissions across the value chain by 2045.

“We took into context that we wanted to become fossil-free, and frankly, also saw the need to invest in our current assets. The combination of these elements led us to understand that the best way forward is to build a modern end-to-end new mill.”

SSAB is a global steel company that employs around 14,500 people and is present in more than 50 countries. SSAB has production facilities in Sweden, Finland and the United States.

Shifting away from coal

The new mill in Luleå is set to deliver significant environmental benefits. Sweden’s total carbon dioxide emissions are expected to decrease by about three million tonnes per year, equivalent to 7% of the country’s total emissions.

The CO2 footprint is set to decrease from 1.7 tonnes to 0.1 tonnes per tonne of steel. Inhalable particulate matter (PM10) emissions are expected to fall from 280 tonnes to 80 tonnes per year. Sulphur dioxide (SO) emissions are also expected to decrease by 250 tonnes per year, which corresponds to approximately a 70% decrease from the current level. Energy utilisation will be about 70% lower compared to the current level, with the main energy source shifting from fossil coal to fossil-free electricity.

Today, the Luleå mill consumes 1.3 million tonnes of fossil coal annually. The new mill will consume roughly 60,000 tonnes of coal annually, which means SSAB will be able to source this as bio-coal when it becomes commercially available in these volumes. Bio-coal is made of organic materials, in this case, out of tree products. It’s mainly added to create a foaming slag in the production process.

A world of micro cycles

NIB’s mission consists of two parts: benefiting the environment; and improving productivity. In this project, the environmental benefits may have overshadowed the productivity improvements. Nevertheless, the latter are still major. For example, it’s calculated that the annual production capacity will grow from 2.0 million tonnes to 2.5 million tonnes.

“It means we will be able to grow our business and our revenue for the first time in many decades.”

It is estimated that fixed costs will decrease annually by 50%, as the new mill will be more flexible and efficient in adjusting volumes. With the new mill, SSAB will be able to adjust the production rate in two hours in response to the variation in business cycles and market demand. This has previously taken about two weeks.

“We’ve basically been stuck with our production decisions. We’re living in a world of micro cycles, and the ability to adjust quickly will be a key factor in the future.”

A transition in technology

The project is fundamentally changing how steel is made, while cutting emissions and improving productivity. What’s the technology behind it?

The new mill will be around 1.5 kilometres long, and all the assets will be in a single line. Raw materials will go in at one end; finished products will come out at the other.

The steel-making process begins by feeding fossil-free sponge iron and scrap to the electric arc furnaces, that generate so much heat it melts into liquid steel. A smaller amount of scrap, recycled steel, is needed to control the temperature.

This liquid steel is channelled to secondary metallurgy, where alloys are added, and some impurities such as nitrogen, sulphur and phosphorus are removed. At the same time, the temperature of the liquid steel is adjusted. The liquid steel then goes through the casting machine to make it solid. Finally, the steel slab is shaped into a steel strip in the rolling mill.

In a nutshell, it’s a technology that is based on fossil-free sponge iron and recirculation of raw materials such as scrap. Instead of production where you lose heat and must then reheat, the heat can be preserved from one process to another.

“There’ll always be a requirement for a certain amount of energy to convert iron oxide to steel – you can’t cheat there. But this fossil-free steel technology will enable SSAB to be competitive for the next 20 to 30 years,” Orrling says.

The technology is proven at other factories around the world. The difference is that in Luleå, everything will be in the same place, minimising the need for internal transport and material handling. A crucial part of this co-location is the collaboration between SSAB, LKAB and Vattenfall, where LKAB supplies the fossil-free sponge iron, and Vattenfall provides the fossil-free electricity.

“From having a piece of scrap, it takes three hours until you have a steel coil. That’s what makes it unique, it currently takes seven days. At the same time, we’re going to be doing it with fossil-free electricity and have removed all the fossil fuel utilization as much far as the technology allows us.”

NIB is co-financing the new mill with two separate 15-year loans, amounting to EUR 310 million. SSAB is a returning NIB client.

“The Nordic Investment Bank has been a trusted and highly supportive partner throughout the Luleå financing process. Coordinating all elements of such a complex transaction required close collaboration, and NIB’s strong commitment and deep understanding of our transition goals were instrumental in shaping a robust sustainable finance structure. NIB’s participation, together with other export credit agencies, not only strengthened the financial foundation of the project but also reinforced market confidence in SSAB’s fossil-free steel journey,” SSAB’s CFO Leena Craelius says.

SSAB is listed on both the NASDAQ Stockholm and NASDAQ Helsinki exchanges. Its largest shareholders include the Swedish state-owned LKAB (10.85%) and the Government of Finland (6.50%).

Over 600 million tonnes of oversupply

It’s well known that the steel market currently faces an oversupply. To be exact, more than 600 million tonnes per year, according to Orrling. The overall costs of the new mill in Luleå are around SEK 50 billion. Why build the mill now?

SSAB feels confident about the future of fossil-free steel and recognizes emerging market demand: the company has signed up around 60 clients as fossil-free steel partners, with a focus on the automotive sector.

Steel is considered a low-hanging fruit for reducing emissions, as clients will soon be able to source it with a much smaller carbon footprint, Orrling says.

“It’s important to remember that even if customers want steel with a lower carbon footprint, they still want a very advanced material. They’ll never compromise on the steel’s mechanical properties,” Orrling says.

One of SSAB’s fossil-free steel partners is Volvo Group.

“To be able to build the world we want to live in, we need to be sustainable both as a company and our products. Steel forms the backbone of our products and as such adds to our carbon footprint. To implement fossil-free steel makes it possible for us to address this issue,” Marcus Andersson, Head of Structure Engineering at Volvo Group, commented in a previous article by SSAB about the partnership.

In addition to emerging demand and the need for modernisation, a third driver behind the new mill project is the EU Emissions Trading System. The overall idea is simple; a high CO2 footprint translates to an increase in costs.

“We thought, it makes no sense to pays this CO2 tax when there is technology available that would allow us to avoid it,” Orrling says.

SSAB is also currently planning the transformation of the Raahe mill in Finland, showing he transition won’t only stay in Luleå. In a traditionally hard-to-abate sector, the future looks more sustainable than ever before.

By Tommy Hellström, Trainee, Communications at NIB